Common Causes of Hydraulic Damage Repair Near Buffalo, NY

Hydraulic systems play a vital role in the operation of industrial equipment across Buffalo, NY, powering everything from heavy machinery on construction sites to complex manufacturing lines in plants. These systems enable precise control and efficient transmission of power, making them indispensable for a wide range of industrial applications. However, when hydraulic systems fail, the consequences can be significant—leading not only to costly downtime but also extensive repair expenses and potential safety hazards.

For equipment operators and maintenance professionals, understanding the most common causes of hydraulic damage repair is crucial for minimizing unexpected disruptions and maximizing the longevity of their machinery. By being informed about the typical failure points and addressing them proactively, businesses can maintain productivity and reduce operational costs. In this article, we’ll explore key reasons behind hydraulic damage repair and highlight proven preventive strategies that can help keep your hydraulic systems running smoothly and reliably.

Root Causes of Hydraulic Damage Repair Near Buffalo, NY

Hydraulic damage repair is frequently necessitated by a handful of typical problems that can be traced back to routine wear or improper maintenance. Recognizing these causes early helps avoid unexpected failures.

Hose Abrasion and Chafing

One of the most common causes of hydraulic damage repair is hose abrasion. Hoses that are exposed to constant friction against metal surfaces or other components can develop wear spots, eventually leading to leaks or bursts. In industrial environments around Buffalo, NY, heavy machinery often exposes hoses to harsh conditions with limited protection, increasing the risk of abrasion.

Worn Seals and O-Rings

Seals and O-rings are critical for maintaining system pressure and preventing hydraulic fluid leaks. Over time, these components degrade due to heat, pressure fluctuations, and chemical exposure. Worn seals compromise system integrity and lead to inefficiencies or complete breakdowns that require immediate hydraulic repair service.

Fluid Contamination

Contaminated hydraulic fluid is a silent culprit behind many system failures. Dirt, water, and metal particles enter hydraulic lines primarily through faulty seals or during routine maintenance if protocols aren’t strictly followed. Contaminants damage pumps, valves, and cylinders, accelerating wear and sometimes causing catastrophic failure that demands hydraulic damage repair.

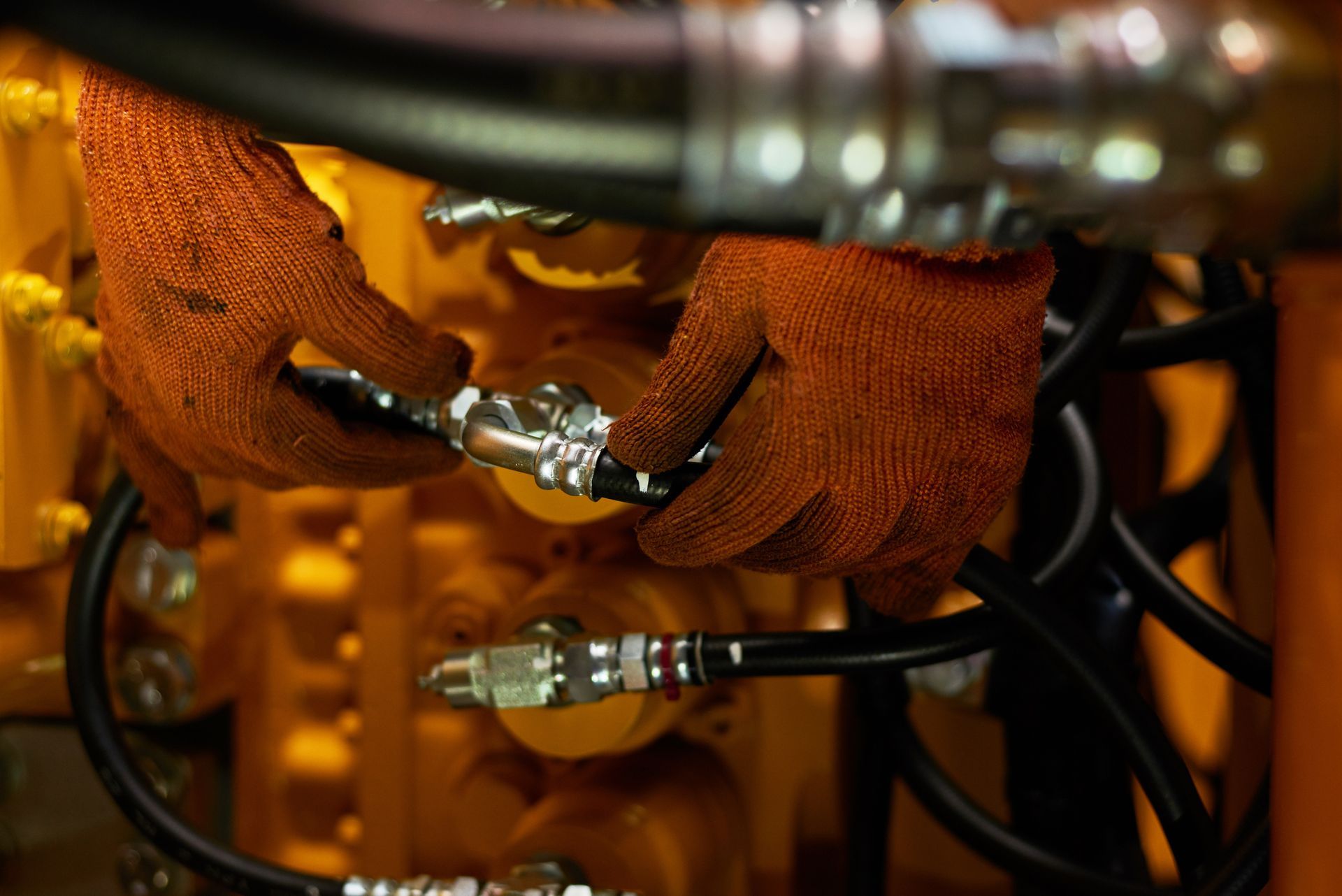

Improper Fittings and Hose Routing

Incorrect hose fittings and poor routing can result in excessive stress on the hydraulic hoses and fittings, increasing the likelihood of leaks and breaks. Improper crimping or mismatch of components may also compromise the whole system, requiring specialized hydraulic repair service. Buffalo, NY’s industrial operators need to ensure that hose installation follows manufacturer guidelines and industry best practices.

Preventive Measures to Reduce Hydraulic Damage Repair Costs

While hydraulic damage repair is sometimes unavoidable, many breakdowns can be prevented with proper care and maintenance. Implementing these best practices will help maintain your hydraulic systems’ reliability.

Conduct Regular Inspections

Routine visual and functional inspections allow operators to detect issues before they escalate. Checking hoses for signs of abrasion, seals for leaks, and fittings for tightness can uncover potential problems early enough to avoid costly repairs. An effective inspection program is a cornerstone in preventing frequent hydraulic damage repair events.

Maintain Proper Fluid Quality

Ensuring hydraulic fluid cleanliness and correct fluid levels is crucial. Using filtration systems, monitoring fluid condition, and replacing the fluid based on manufacturer recommendations prevent contamination that accelerates component wear. Clean fluid protects expensive equipment from irreparable damage.

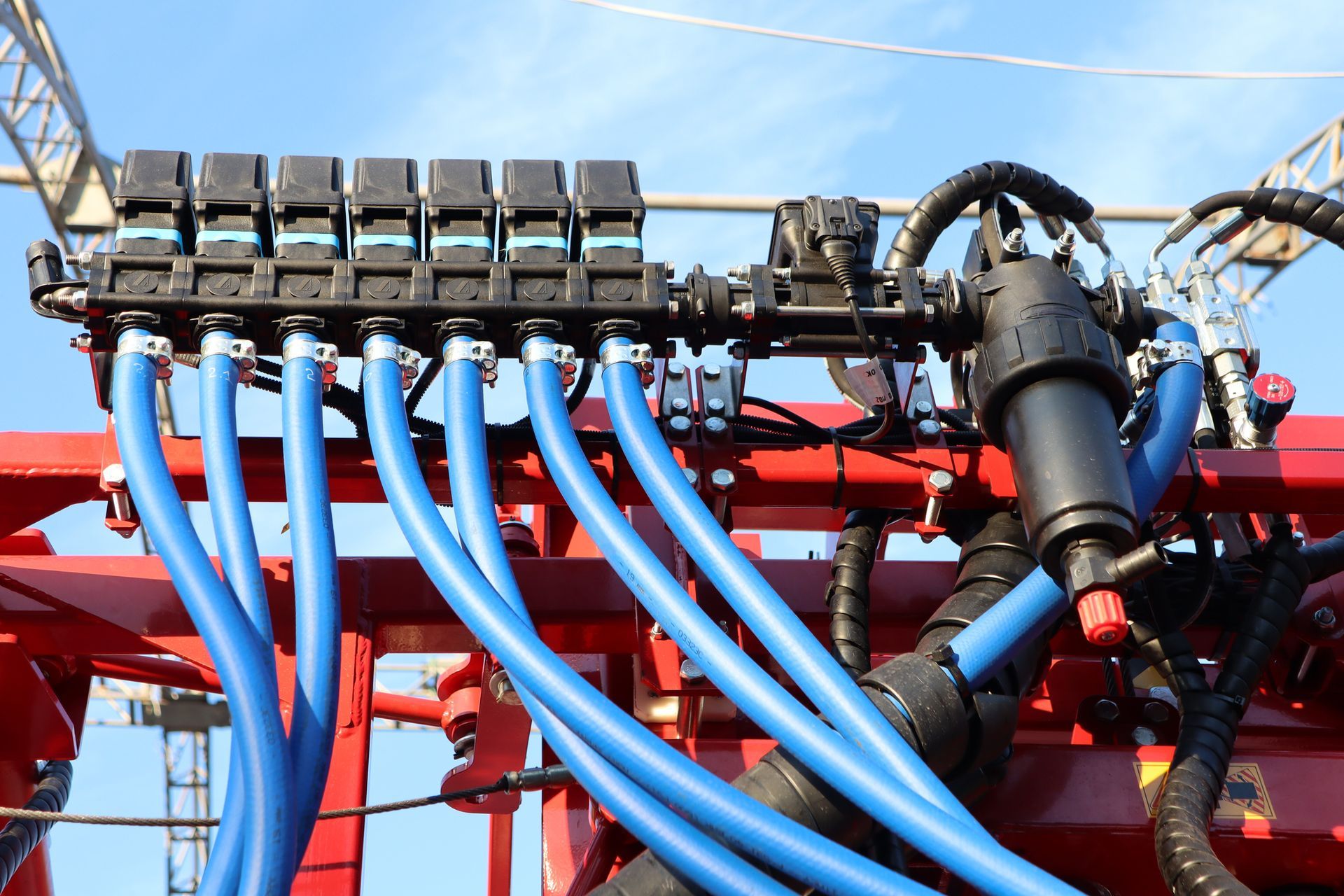

Use Protective Sleeves and Cap & Plug Kits

Protective sleeves safeguard hydraulic hoses from abrasion and environmental damage, extending hose life considerably. Additionally, cap & plug kits prevent contamination during hose disconnection or storage. These protective measures are straightforward yet effective components of a proactive maintenance strategy.

Employ Correct Hose Routing Techniques

Proper hose routing minimizes bending and twisting stresses, which contribute to premature hose failure. Ensuring adequate slack, avoiding sharp bends, and securing hoses away from heat sources or moving parts improves system longevity. This practice is particularly important for equipment operating in the rugged environments surrounding Buffalo, NY.

Partner With Ferry Hydraulics for Hydraulic Repair Service and Prevention

Understanding the root causes of hydraulic damage repair is only half the battle—preventing these issues requires expert insight and dedicated maintenance. Ferry Hydraulics offers comprehensive hydraulic repair services to tackle any emergency repairs efficiently, minimizing downtime for your operations near Buffalo, NY. Beyond repairs, Ferry Hydraulics also serves as a trusted partner in implementing preventive maintenance programs designed to protect your investment.

Their skilled technicians provide expert inspections, fluid analysis, and recommendations on hose protection and routing to help prevent future damage. Whether you require emergency hydraulic damage repair or want to establish a robust maintenance plan, Ferry Hydraulics is your dependable resource. Don’t wait for a hydraulic system failure to disrupt your operations.

Contact Ferry Hydraulics today

for expert hydraulic repair service and prevention strategies that keep your equipment running smoothly and efficiently.